What SOMAX Can Do

Molds are the core of manufacturing that supports all areas of industries.

We at SOMAX Co., Ltd. a general manufacturer of mold maintenance equipment, can do all of the research, development,

manufacturing and marketing of mold maintenance equipment such as mold cleaning machines, mold temperature control pipe cleaning machines

and mold repair welding machines, as well as providing specified cleaning solutions.

We provide a one-stop solution for any mold maintenance challenges at worksites with our products.

The Advantages of

SOMAX Co., Ltd.

Strengths

-

Over

30 years of research on mold maintenance -

A market share of 32% and cumulative sales of over

8,000 -

In-house research, development, manufacturing and marketing

Our core products

support manufacturing

Supports manufacturing

We solve a variety of challenges for manufacturing companies!

Action & Problem Solving-

For resin injection molding companies

Challenge

Plasticizers that contain molding gas, a corrosive substance, rusts molds.

If left untreated, it causes further rusting which decreases the life of the molds.Solution

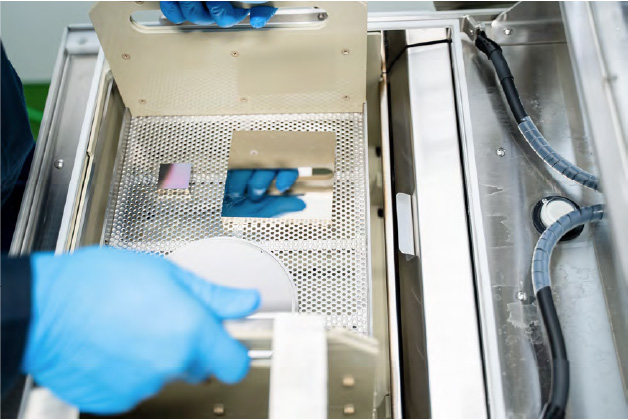

Removing completely the dirt penetrated into molds with the mold cleaning machine the CLIPIKA ACE

Click here for product information

(ultrasonic waves + electrolysis + a cleaning solution with an optimal composition)

not only returns molds to nearly new, but also prevents molds from corroding. -

For rubber molding companies

Challenge

The cleaning of vulcanizing gas, which may cause rubber scraps or corrosion, is essential for rubber molds.

However, just using an alkali cleaning agent and brushing at high temperature are insufficient for cleaning grooves and holes.

In addition, the fumes from alkali cleaning agents are harmful.Solution

The mold cleaning machine CLIPIKA ACE cleans grooves and holes completely without generating toxic fumes.

Click here for product information

It also does not damage plating layers. -

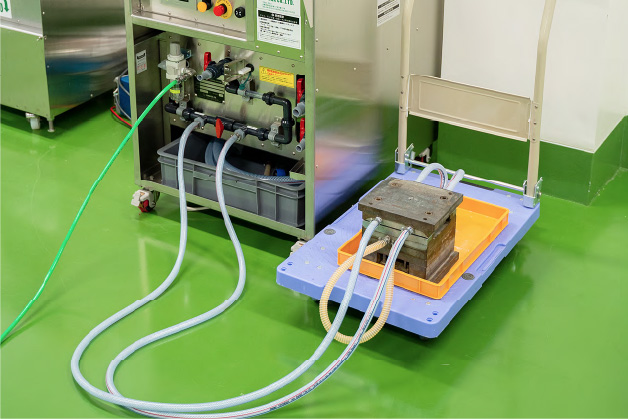

For die-casting companies

Challenge

The cooling efficiency of molds is decreased, and there are increasing mold problems including burning and defective casting such as cavities, broken pins and cracks.

Solution

The mold temperature control pipe cleaning machine the SUKATTOSU removes completely rust and scale in temperature control pipes of large-sized molds in its large volume tank of 60 liters and so improves their cooling efficiency.

Click here for product information

In addition to rust removal, it forms rust preventive films; therefore, it is ideal for preventive maintenance. -

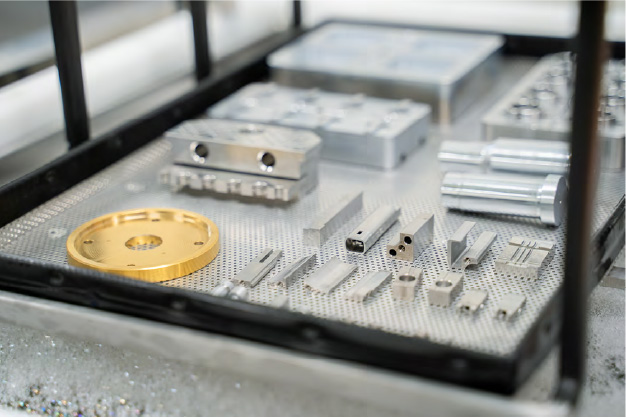

For metal stamping companies

Challenge

The movement of molds is worsened due to oil burn and rust, and molds are rapidly worn out.

There are many parts, so it takes time to remove rust.Solution

Cleaning many parts collectively at once with the mold cleaning machine

Click here for product information

the CLIPIKA ACE can significantly decrease maintenance time.

In addition, the life of molds is extended because burn and rust are removed without scraping.